Disco updates semi-automatic dicing saws

Improved communication support allows timely control of multiple dicing saws

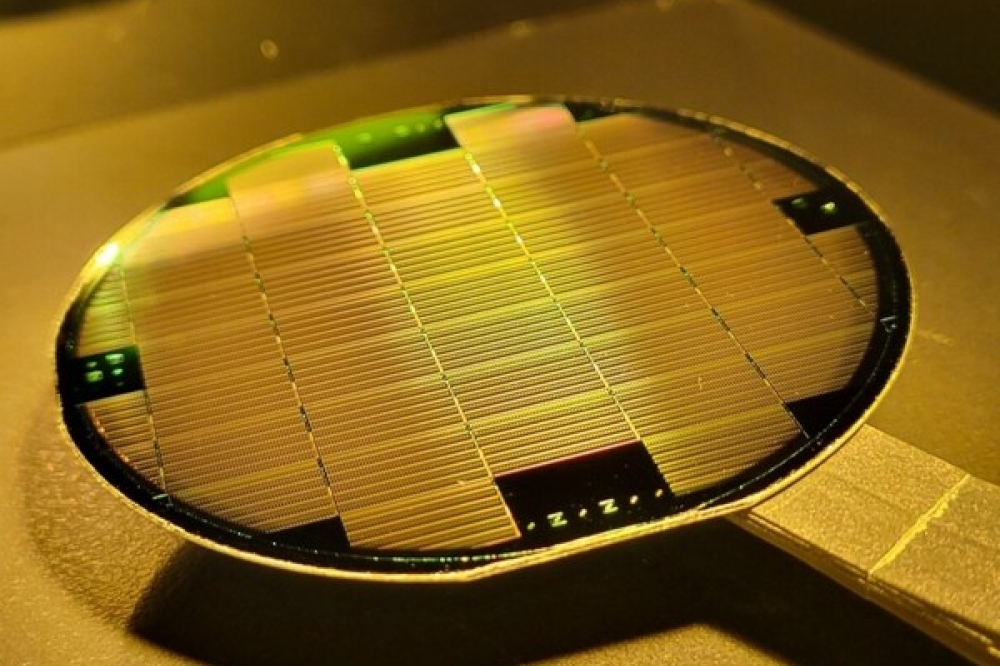

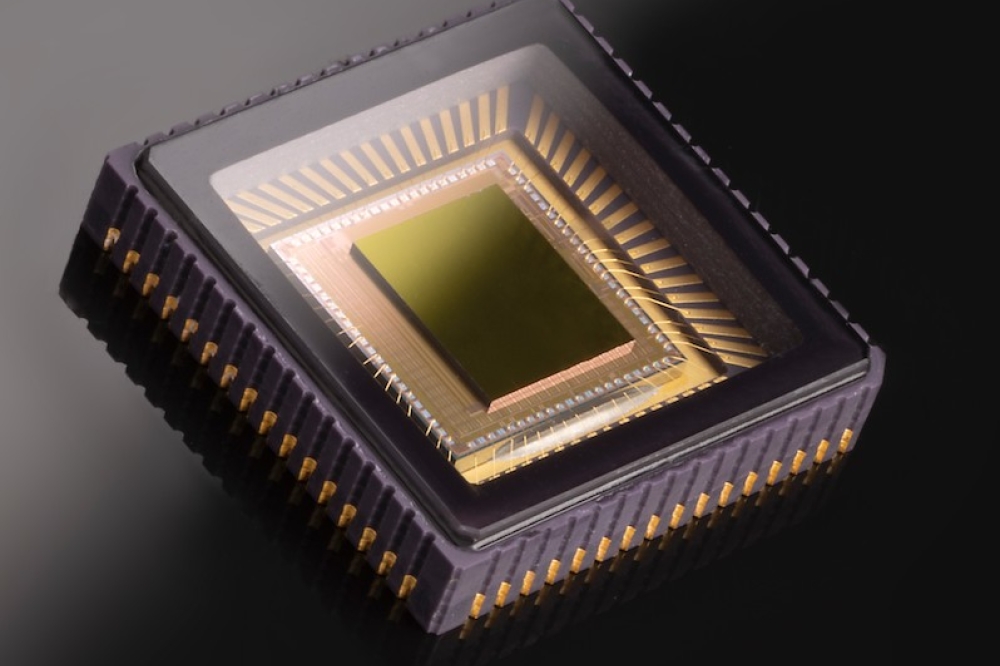

Disco Corporation has announced the DAD3351, a new semi-automatic dicing saw with a 10 percent reduced footprint, designed for 200mm diameter wafers.

The existing semi-automatic dicing saw DAD3350 is a best-selling model that flexibly supports a wide range of workpieces and has been delivered to many companies around the world. The newly developed DAD3351 has inherited the features of DAD3350, with a high-rigidity bridge-type frame for the spindle axis, which can withstand high-load processing, and high extensibility to support various options and user-specified specifications.

By increasing the axis speed through an improvement in motor performance and by optimising the parameters, unit per hour has been improved by 5 percent (compared to DAD3350). The footprint has been reduced by 10 percent compared to DAD3350.

As well as improvements (above), the company has developed two further models DAD3361 and DAD3431 and completed a model change for all nine of its semi-automatic dicing saw models, with improved productivity and communication support in all its models.

Communication functions were limited in existing models, which made it difficult to control them centrally. For mass production, multiple units must be installed and simultaneously operated in parallel due to the time needed to process difficult-to-cut materials. For this reason, there has been demand for communication support that would enable timely control of multiple dicing saws. Given this background, Disco has updated all nine existing semi-automatic dicing saw models with this support.