Fraunhofer IAF makes QCLs more affordable

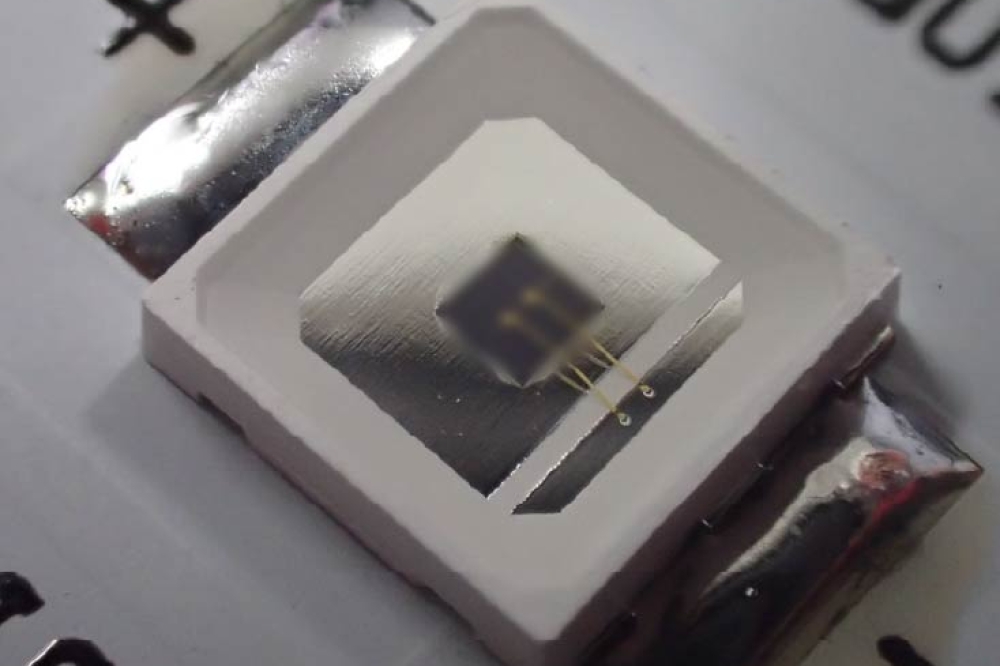

Fraunhofer IAF has developed a semi-automated manufacturing process for making resonantly tuneable quantum cascade laser modules (MOEMS-EC-QCLs).

The German research organisation will present the process, which cuts costs and accelerates manufacturing, at the Laser World of Photonics in Munich (from June 24 to 27, 2025). Visitors will be shown a multi-core system that combines four modules via multiplexing and achieves effective spectral measurement speeds of over 1 million wave numbers per second.

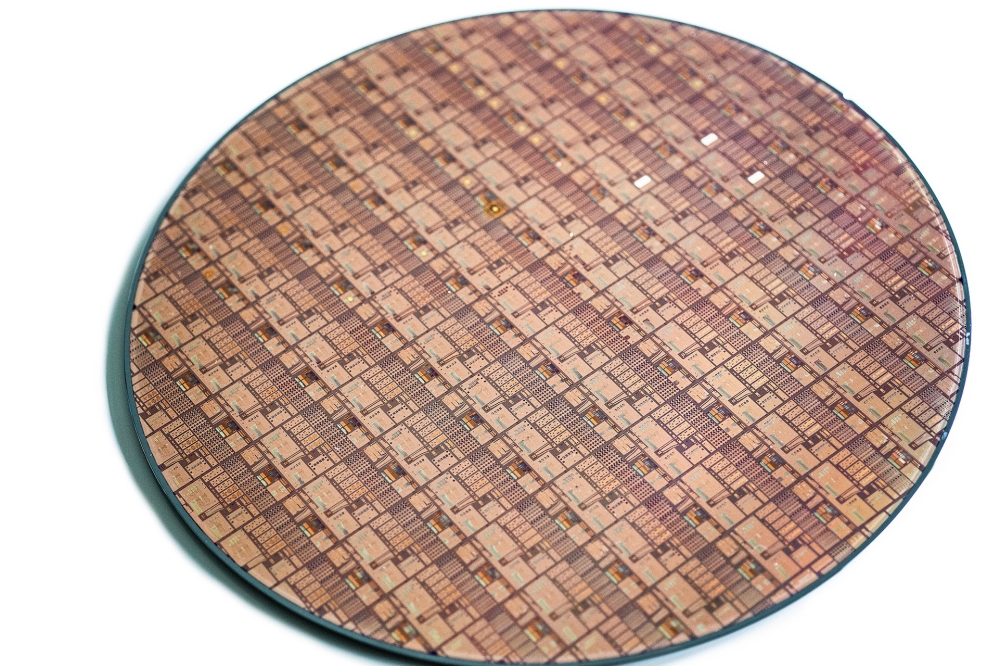

Resonantly tuneable QCLs are high-performance laser light sources for a wide range of spectroscopy applications in the mid-infrared (MIR) range. However, the production of QCL modules has been relatively complex and expensive.

The Fraunhofer IAF process simplifies the production with a MOEMS (micro-opto-electro-mechanical system) grating scanner in an external optical cavity (EC), making it more cost-efficient. The MOEMS-EC-QCL technology was developed by Fraunhofer IAF in collaboration with the Fraunhofer Institute for Photonic Microsystems IPMS.

Previously, it was only possible to assemble the modules by hand because they had to be actively adjusted. The new process automates the assembly process of MOEMS-EC-QCLs with the help of a pick-and-place system, which significantly reduces manufacturing costs.

In addition, Fraunhofer IAF says it has developed a flexible and scalable method for efficiently combining multiple laser sources into a multi-core system. Individual QCL modules have only a limited spectral width. By combining modules with supplementary spectral ranges, application-specific multi-core systems can be configured that achieve effective spectral measurement speeds of more than 1 million wavenumbers per second.

Advantages and areas of application of MOEMS-EC-QCLs

MOEMS-EC-QCLs are suitable for a wide range of spectroscopy methods (transmission, backscattering, ATR, microfluidic, point-of-interest spectroscopy) and allow complete infrared spectra to be recorded in just 1 ms.

Application areas include semiconductor measurement technology to determine epitaxial layer thicknesses and their compositions; process analytics to optimise chemical reactions; process control to test coatings; security technology to detect hazardous substances or intoxicants; and in the pharmaceutical industry for quality assurance.

“The market potential of MOEMS-EC-QCLs is enormous. The high brilliance in combination with spectral tuneability due to the use of MOEMS diffraction gratings enables the further development of measurement methods based on FTIR spectroscopy and their use for inline measurement technology,” explains Marko Haertelt, leader of the Laser Measurement Technology Group at Fraunhofer IAF.

“We have now been able to bring the technology to an industry-ready level in terms of cost and availability: on the one hand, by placing the production of MOEMS-EC-QCL modules on a semi-automated manufacturing basis; on the other hand, by using a scalable approach to couple modules with complementary spectral ranges. The latter significantly reduces the number of different modules required to cover the entire MIR range from 4 to 11 µm, thereby achieving the necessary economies of scale,” says Haertelt.