Retro-tech revolutionises the deep UV

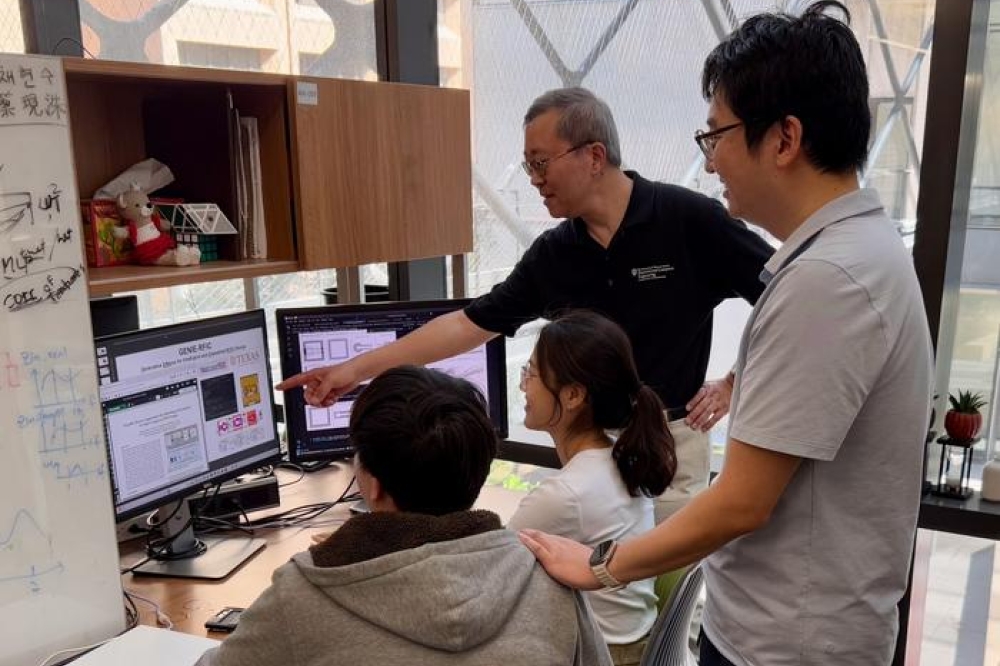

Compact sources of deep-UV emission from NS Nanotech are providing air purification through cathodoluminescence of boron nitride.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

When it comes to device design, our industry is quite insular. We focus on improving performance by optimising epitaxy or the architecture of our chips. But at times we might be missing a trick, and would benefit from approaches involving more out-of-the-box thinking.

Doing just that with considerable success is the Michigan-based start-up NS Nanotech. Drawing on cathode-ray tube technology that lies at the very heart of the televisions of yesteryear, it has just released an improved version of its cathodoluminescence-based 215 nm source that’s a compelling candidate for air purification in relatively confined public spaces.

The NS Nanotech source goes deeper than AlGaN-based UV LEDs – they have been under development for decades, with developers striving to improve the efficiency and output, so that those emitters could be deployed in various applications, including curing and the purification of air, water and surfaces. Motivation for the development of deep-UV LEDs is the addressing of many weaknesses of the incumbent solution, a gas-discharge lamp that is fragile, bulky, and is some cases contains mercury, which is of great concern to humanity’s health. However, while the power produced by deep-UV LEDs continues to increase, it’s not that high, limiting success.

As well as offering more power, the technology from NS Nanotech produces emission at a preferable wavelength. While no light in the UV is perfectly safe to humans, the most damaging to the skin and eyes is in the range 240 nm to 280 nm.

“It's right where mercury bulbs are, where all the UVC LEDs are,” says NS Nanotech CEO and co-founder Seth Coe-Sullivan. “The lowest commercial LED available is at 235, which isn't quite as bad as 240, but it's awful close.”

Coe-Sullivan points out that the only two commercial sources beneath that harmful band are krypton chloride bulbs, with an emission peak at 222 nm, and NS Nanotech’s source.

Note that there is little to be gained by going below 200 nm, as light in this spectral domain is absorbed by oxygen, hampering its transmission.

The primary application for far-UVC ShortWaveLight 215 nm products made by NS Nanotech is to sterilise the air in vehicles.

Superior successor

Back in October 2024, NS Nanotech introduced its first far-UVC ShortWaveLight 215 nm emitter; and recently, it has unveiled a second-generation variant, with an output of 500 µW, 60 percent higher than its predecessor.

“Compared to any far-UVC LEDs on the planet, this is massively powerful, certainly the most powerful semiconductor device at this colour,” says Coe-Sullivan.

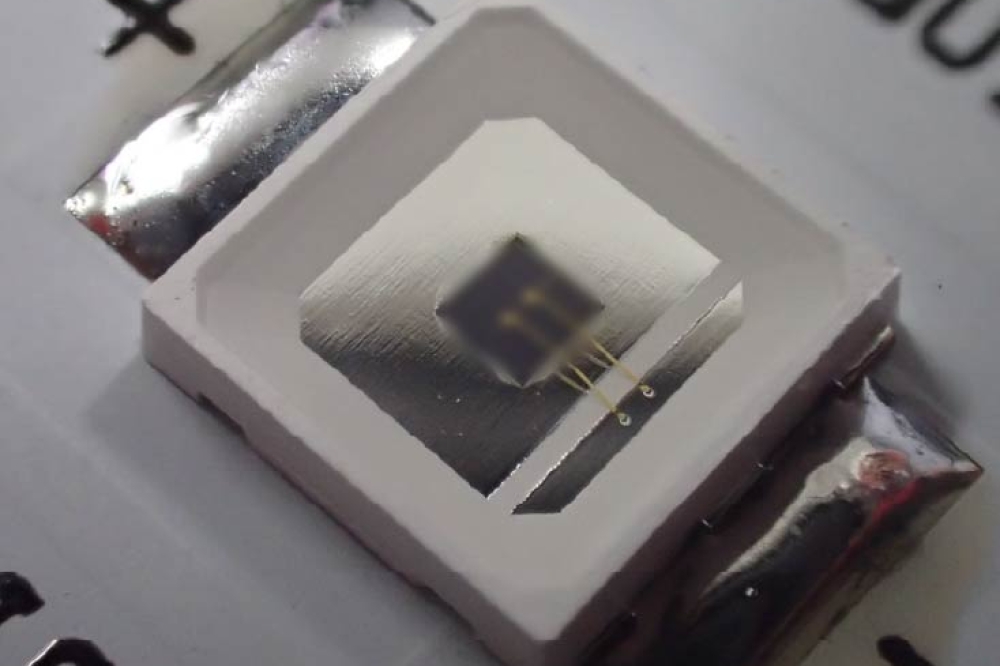

Both generations of far-UVC ShortWaveLight 215 nm emitter are vacuum tube devices that feature semiconductor emitters. These products employ a filament, providing hot electrons that are accelerated to semiconducting material, which emits UV light via cathodoluminescence. The increase in the output power of the successor comes from optimising the vacuum tube before pinch off.

AlN vs BN

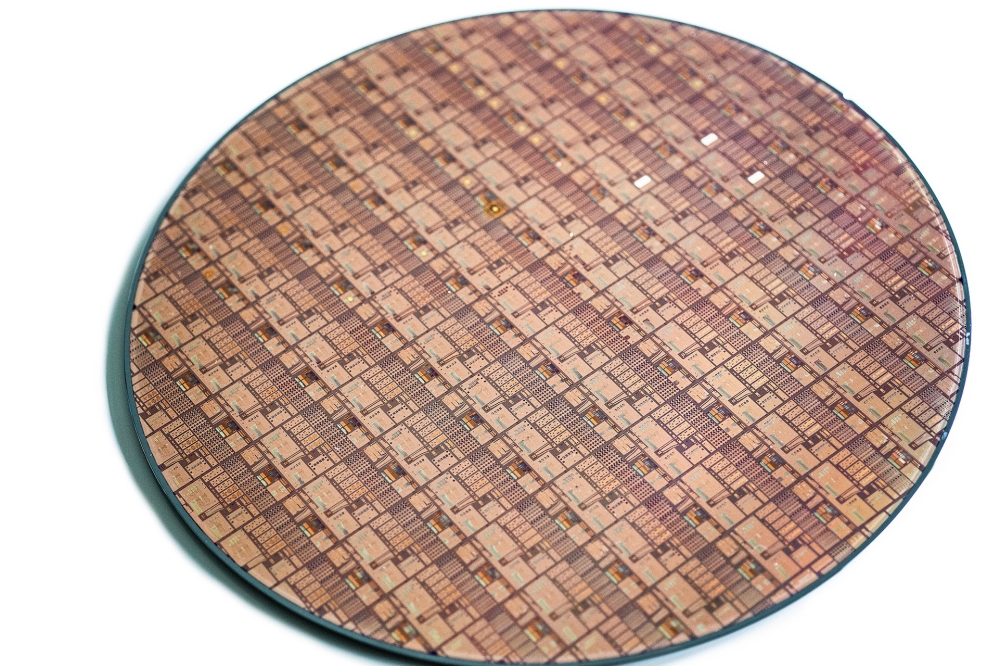

The obvious candidate material for providing cathodoluminescence is AlN, a key semiconductor for producing deep UV LEDs. But NS Nanotech uses BN, as this has better bandgap emission when quantum wells are not employed.

“If you just buy bulk boron nitride powder, you'll get essentially zero emission at 215 nanometres,” warns Coe-Sullivan. “You'll get all defect emission, which is far lower energy than the bandgap.”

To avoid this fate, the team at NS Nanotech employs a refined process for producing BN powders, involving licensing technology from Japan. The BN bulk powder is coated on a disc about a square centimetre in size, with cathodoluminescence providing 215 nm emission of the company’s products, which are roughly the size of a golf ball.

The primary application for NS Nanotech’s technology is reducing the spread of diseases in small, confined spaces. This approach to improving public health is known to succeed, thanks to the pioneering work of Niels Ryberg Finsen, who received the 1903 Nobel Prize for Medicine for studies into the use of deep-UV emission to disable micro-organisms.

Interest in using deep-UV sources to kill viruses rocketed during the pandemic, but has fallen away, with many wanting to simply move on from those difficult times. However, while this view is understandable, failing to learn lessons from the Covid-19 outbreak leaves humanity vulnerable to the next pandemic, which could take many forms.

Speculating on possibilities, Coe-Sullivan remarks: “Is it a measles outbreak in Texas? Is it the bird flu crossing over to humans? Is it something we can't name?” He has no doubt that the likelihood of another pandemic is only going to increase year by year, pointing out that the planet’s population is increasing, many are living closer to animals, and germ-sharing is on an upward curve.

One significant opportunity for passing on germs occurs in confined spaces, such as those found in cars. It is here that NS Nanotech is hoping to make difference, promoting its products for deployment in private cars, Ubers, ambulances and air ambulances.

“Vibration testing has been really key,” claims Coe-Sullivan, revealing that one of the company’s 215 nm sources has been fitted in a pick-up truck that’s been driven on dirt roads for last six months. Encouragingly, this field test has not produced any degradation to the deep-UV product.

In movie theatres, there’s also much interest in using sources in the 200 nm-230 nm band to kill bacteria. Here, more power is needed, so lamps based on krypton chloride that emit around 30 milliwatts are used.

“Krypton chlorine is a great product,” says Coe-Sullivan. “But if you're in a car, Krypton chlorine is the wrong product, and our product is the right product.”

What’s also clear is that while the white-emitting filament bulb now belongs in the museum, other vacuum-based technologies are going strong, and will have a role to play in society for many more years.